December 12, 2025

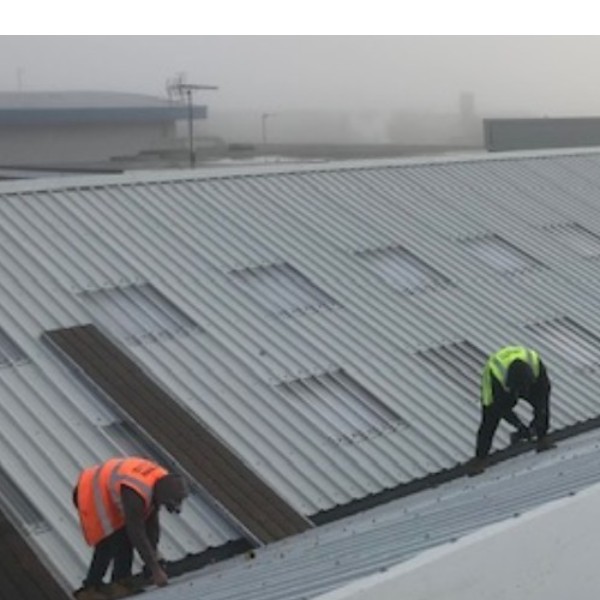

Industrial roofing systems endure a lot of punishment. Pair the British weather and the vibration of the machinery with years of pooling water and you've got challenges domestic roofing systems don't face. But industrial roof systems are often one of the least thought about areas of a business roof system until a disaster occurs. Industrial roofing systems endure a lot of punishment. Pair the British weather and the vibration of the machinery with years of pooling water and you've got challenges domestic roofing systems don't face. But industrial roof systems are often one of the least thought about areas of a business roof system until a disaster occurs.

In reality, industrial roofing systems can last decades with proper maintenance. Ignoring preventative maintenance, however, will lead to untimely failures, costly emergency repair situations, and time lost that cuts into profits. Here are some tips to avoid costly oversights with regard to industrial roof maintenance.

In order to maintain something properly, one has to know exactly what they are working with. Single-ply membranes, built-up roofing, and metal systems all have various different system needs. Some are more sensitive to different cleaning products, and some systems have inspection methods that can't be used. If you are unsure of what is covering your building, you need to find out. This is perhaps the most important information that will allow you to create a suitable maintenance approach to your industrial roofing system.

For example, metal roofing systems need to be inspected periodically to check for corrosion and missing fasteners. Detected missing fasteners often lead to roof leaks and/or moisture infection of the insulation. Most membrane roofing systems are more concerned with seam punctures and the integrity of the system’s seams. This type of understanding will go a long way in providing preventative maintenance information for industrial roofing system owners.

Many industrial roofs fail because of a lack of oversight and malfunctions that go unaddressed for too long. This means someone misses a small defect that could be mitigated for less than a few hundred pounds, which can cross the barriers of a £20,000 replacement at a later date if nobody catches these issues early.

Perform adequately scheduled inspections every six months, preferably every have a spring and fall inspection scheduled. Don't send someone up for a quick glance accompanied by a clipboard. You need a thorough inspection, one that includes drainage systems, flashing, penetrations, and the entire membrane or surface. Also, have someone go up there after storms. High winds and heavy storms can inflict damage that might not be visible from the ground.

Water is the biggest enemy of the entire roofing system. Every industrial roof is at risk of failure if there's poor water drainage, all the while, the quality of the installation can be good. Landscape debris, blocked gutters, clogged drains, and debris can all lead to water ponding, which is a major problem to water leaks, structural deterioration, early roof failure.

Keep your gutters and water drainage points clear, especially during autumn, when leaves are all over the ground. There should be no standing water on your roof for more than 48 hours after rain. If water ponded on your roof for a long period of time, you probably have a drainage problem that could lead to a lot of damage on your roof. Drainage is a significant risk that needs attention.

Those minor problems like tiny blisters in your membrane, loose flashing on pariet wall, or not securing a fastener into your metal panel may seem insignificant, but that's not the case. Water exploits weak points like these mercilessly.

These minor problems should be repaired immediately after spotting them. Spending a little time on minor repairs is vital to prevent spending a lot of time on major repairs. It's spending economy, investing a small amount in preventative maintenance is way more valuable than losing lots of money to emergency repairs.

Commonly, industrial roofs receive some amount of foot traffic from maintenance workers, HVAC technicians, and other trades. Every foot that crosses your roof is a potential source of damage. Punctures, compressed insulation, and dislocation of materials are unlike be a result of someone being careless.

Set out contact prescribed walkways and ensure that anybody coming onto your roof knows the dos and don'ts for where they may and may not walk. Your roof should be clear. It's neither a storage area nor a shortcut. Sure, those air condintioners need routine servicing, but it doesn't mean that technicians are allowed to walk all over your membrane.

Most roof leaks come from the edges, transitions, and roof penetrations; therefore, it is essential to do proper and frequent maintenance in these areas. The edges of the roof, where flashing is installed from the vents, skylights, and other equipment, get more movement and can cause more stress and failure than other roof areas.

Sealants and caulking should also be inspected. They fail faster than the roofing system and need to be replaced more frequently. This is even more important for roof equipment; penetrations need to be sealed for proper protection.

Some maintenance responsibilities can be taken care of in-house. Other tasks need to be handled by the pros and can’t be DIY-ed. People often try to save money by doing complicated repairs, but it usually ends badly. If you’re ever in doubt, it’s best to get help.

For expert industrial roofing and repair services, check out Durasteel Roofing Services. Having a reliable partner for industrial roofing and maintenance can make the difference in whether a roof fails prematurely and whether it lasts its expected lifespan.